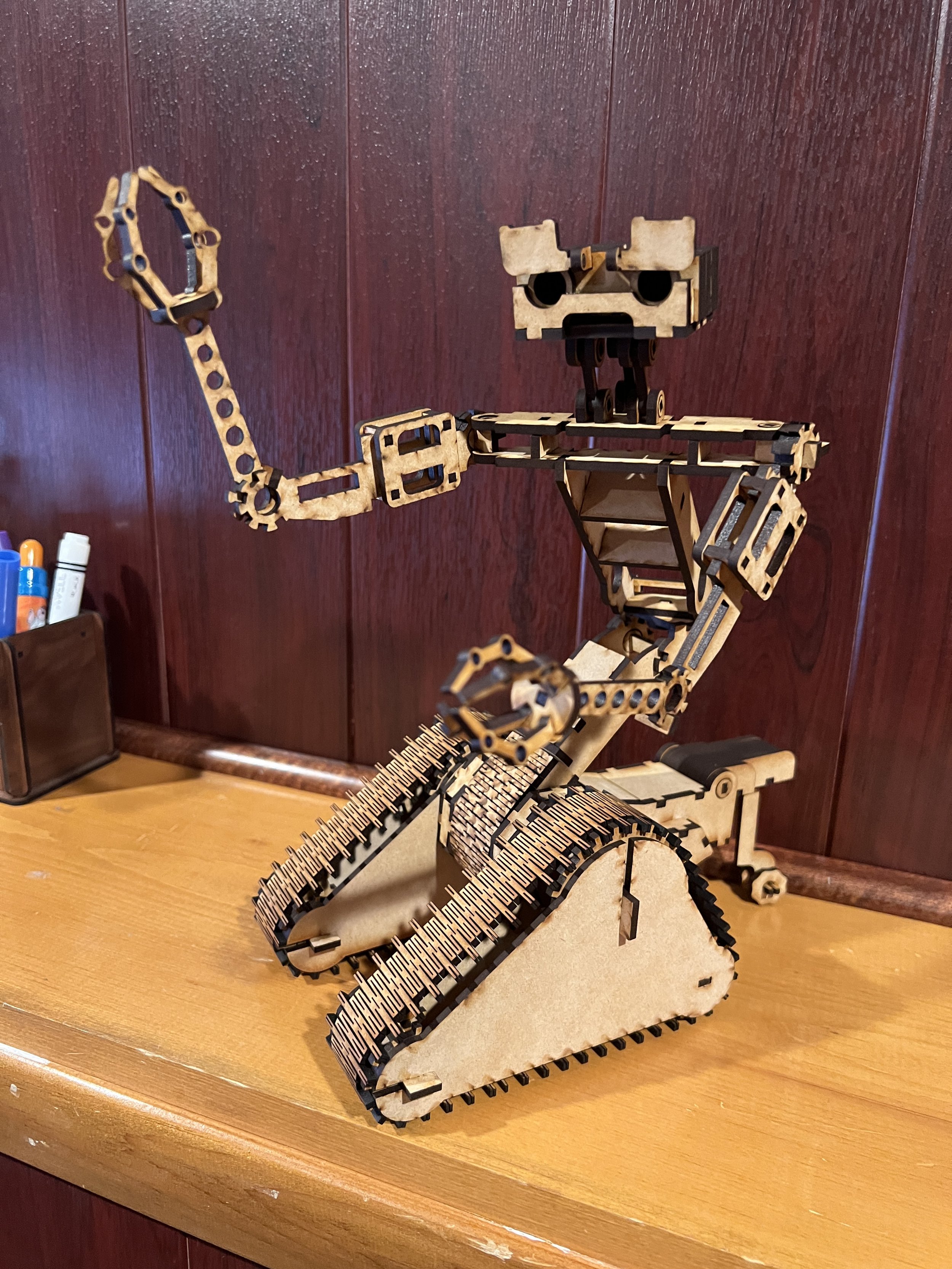

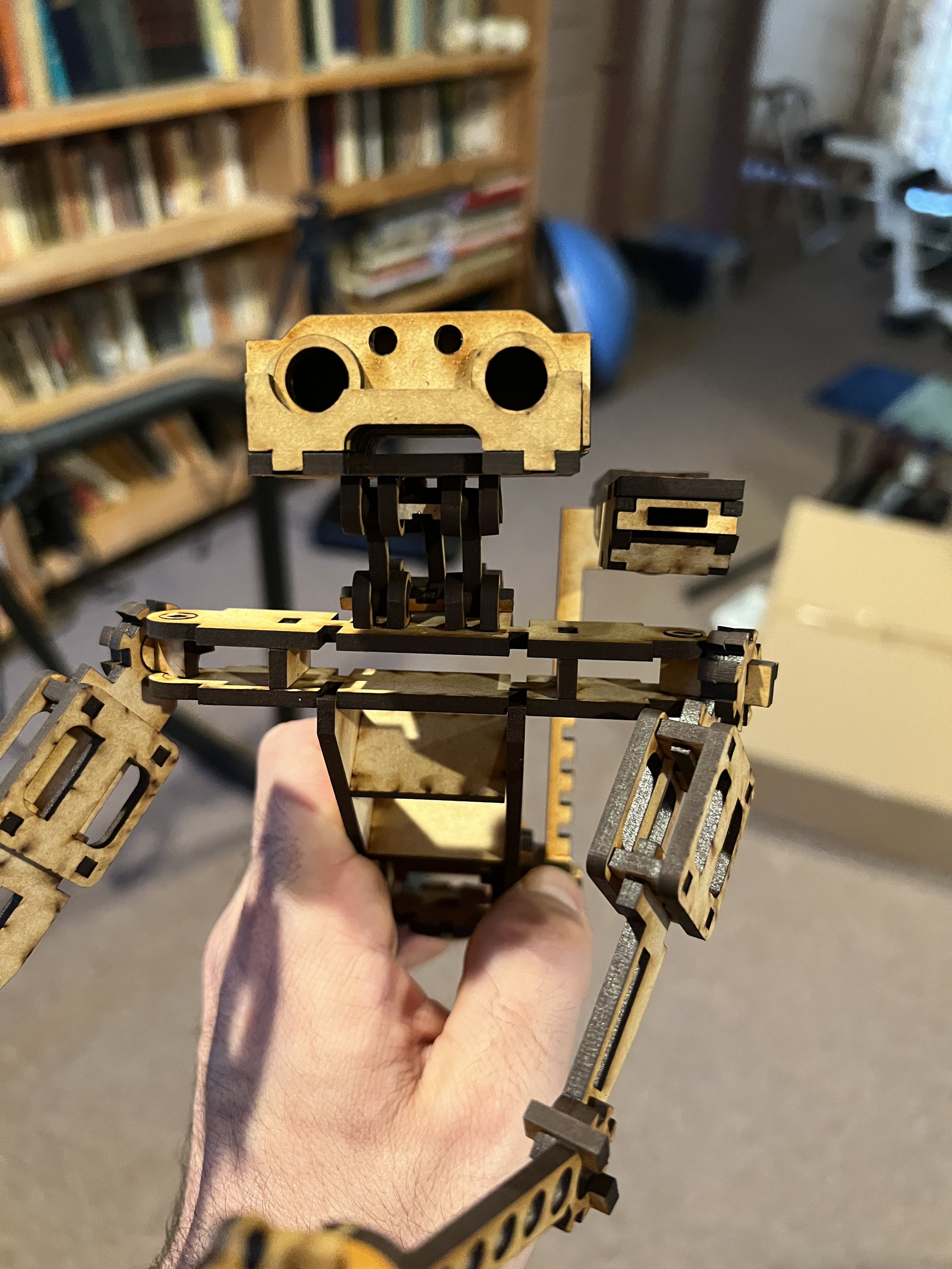

Number 5 is alive!!!

Johnny Five is alive!!

No disassemble (again)!

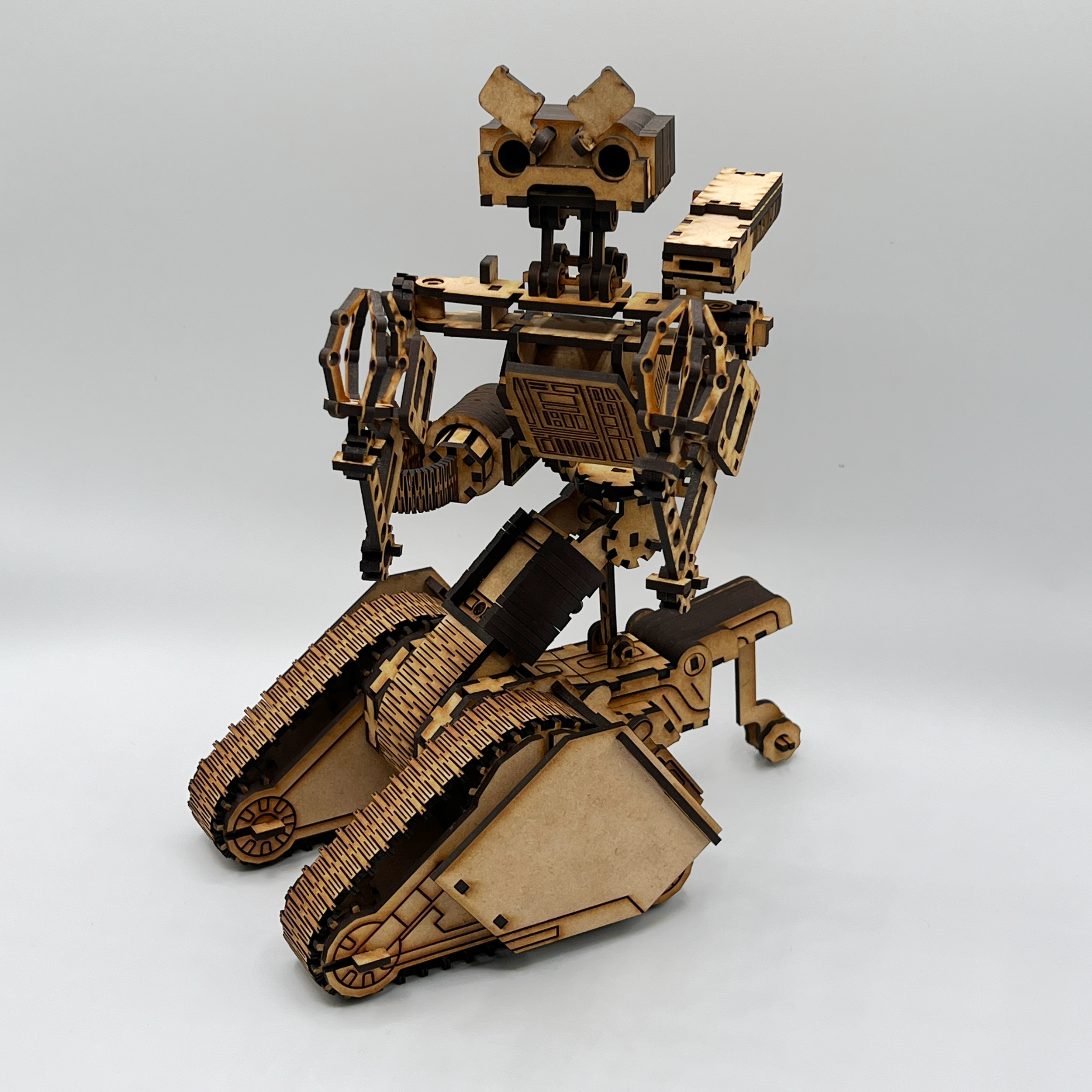

One of my earliest - and favorite childhood movies - was the 1986 cult classic Short Circuit. I saw it with my mother in a theater while I was growing up in Russia, with a pretty awful translation from English to Russian. I realized how bad the translation was quite a few years later when I moved to the US, began to speak English at a much higher level, and watched Short Circuit again, in English this time.

The movie is about a robot that, through the unlikely event of being struck by lightning, comes alive, becoming more human and empathetic than many of the humans he encounters in the movie. In the process of becoming more human, he takes on the name Johnny Five, rather than continuing to go by Number 5, his more official robotic monicker.

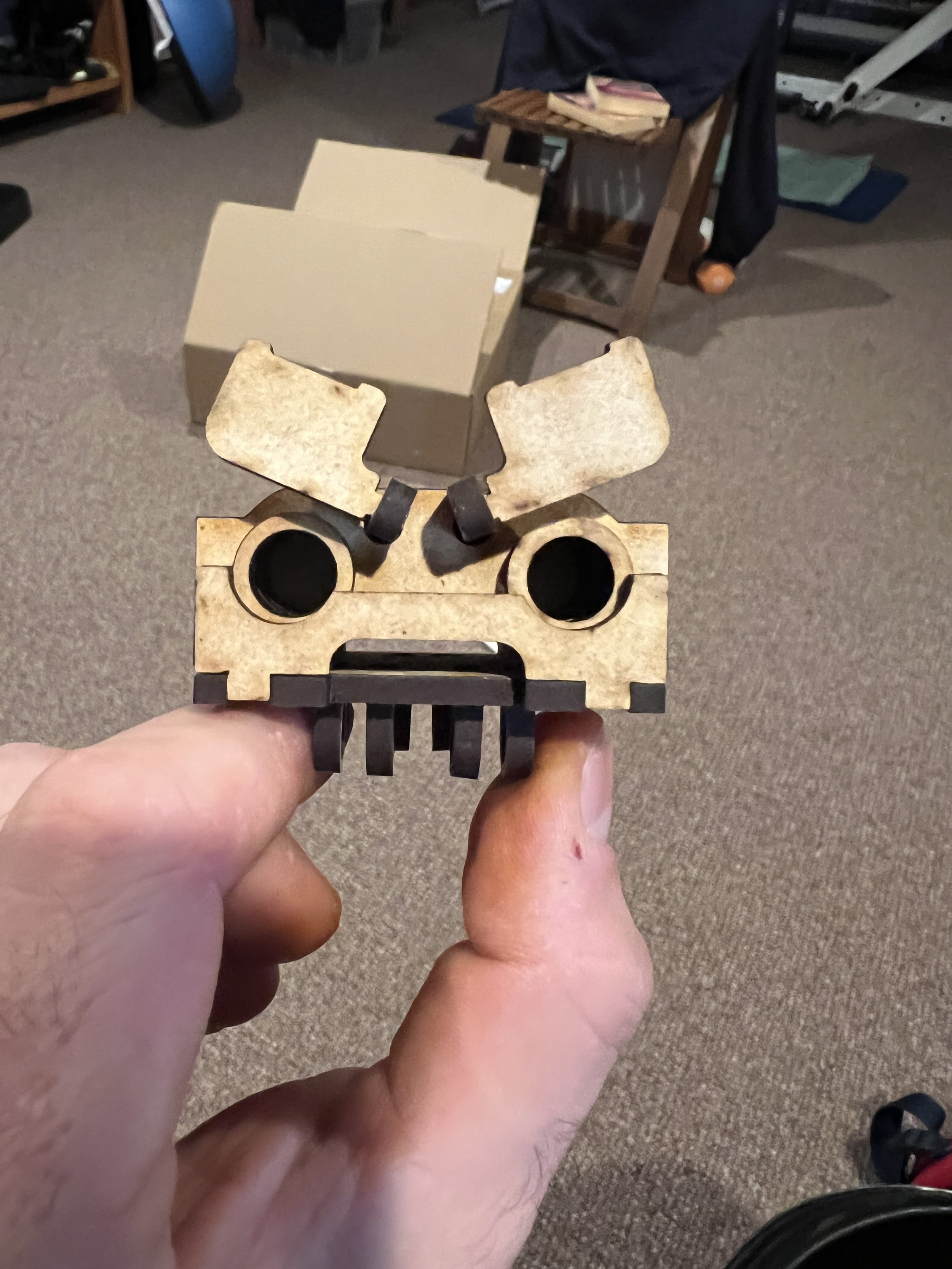

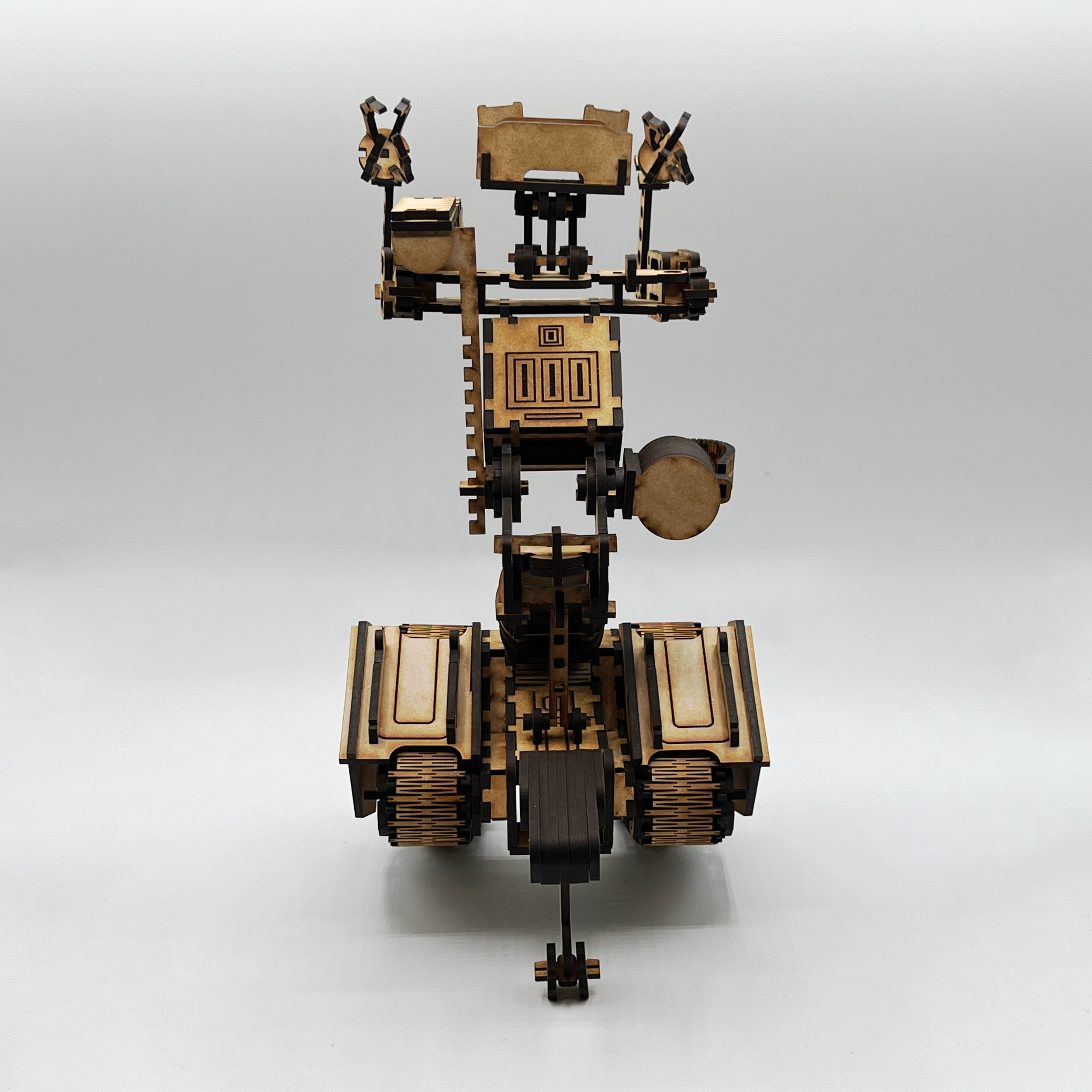

Yes, Johnny Five is giving baaaad humans the middle finger. He is tired of them constantly trying to disassemble him!

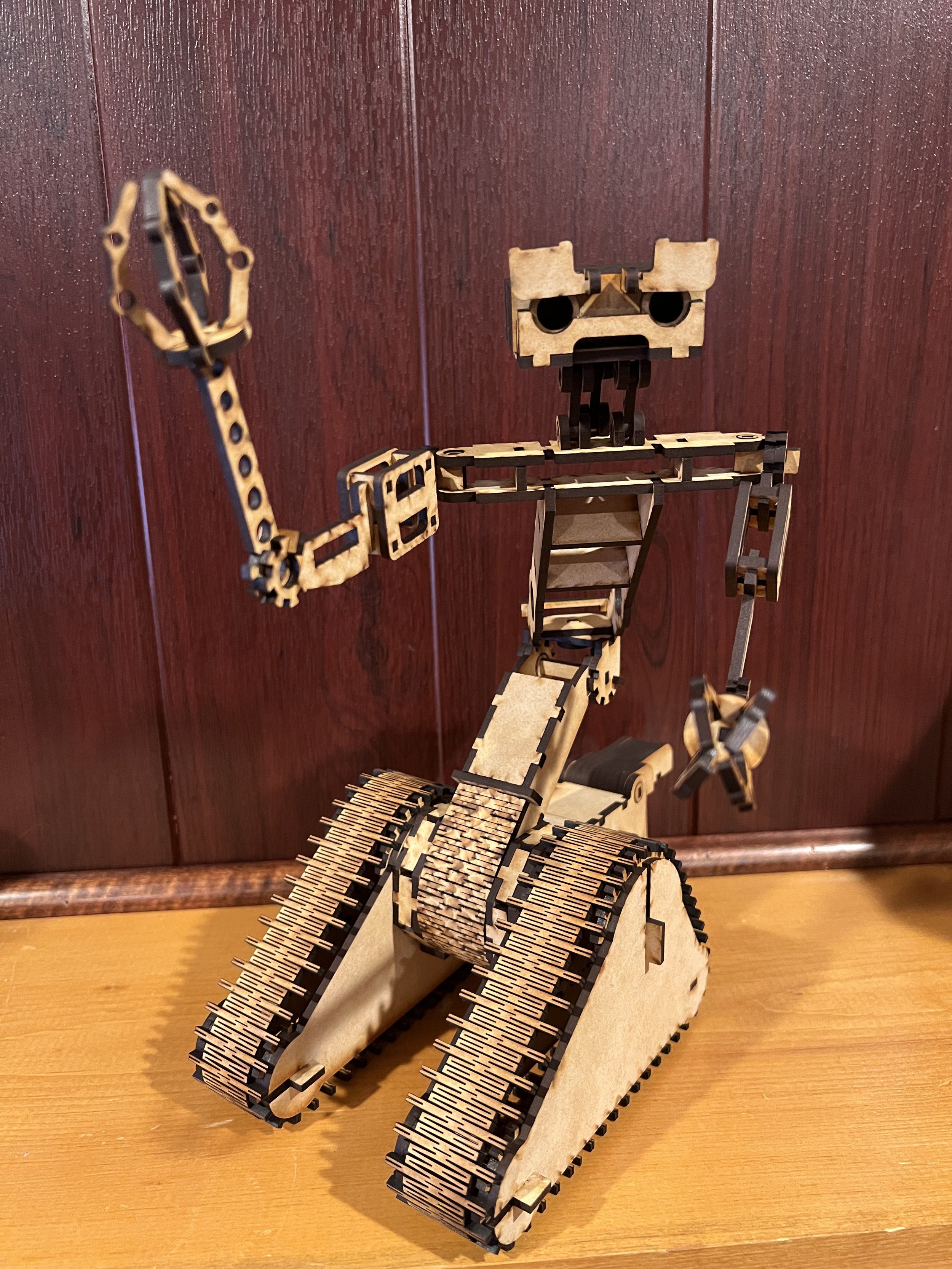

A few weeks ago I decided to watch Short Circuit 1 and 2 (don’t judge me, I judge myself for watching the sequel!). I am not sure what brought on the sudden desire to become a toy maker, but I thought how cool it would be to make a Johnny Five robot out of wood. And, over the course of about 3 weeks, that’s exactly what I set out to do. I didn’t know how it would turn out or what it would look like, but I knew that I wanted to engineer Johnny Five completely from scratch and make him as functional as possible. I also wanted to assemble him without any glue or adhesive, so everything would have to either snap or slide together.

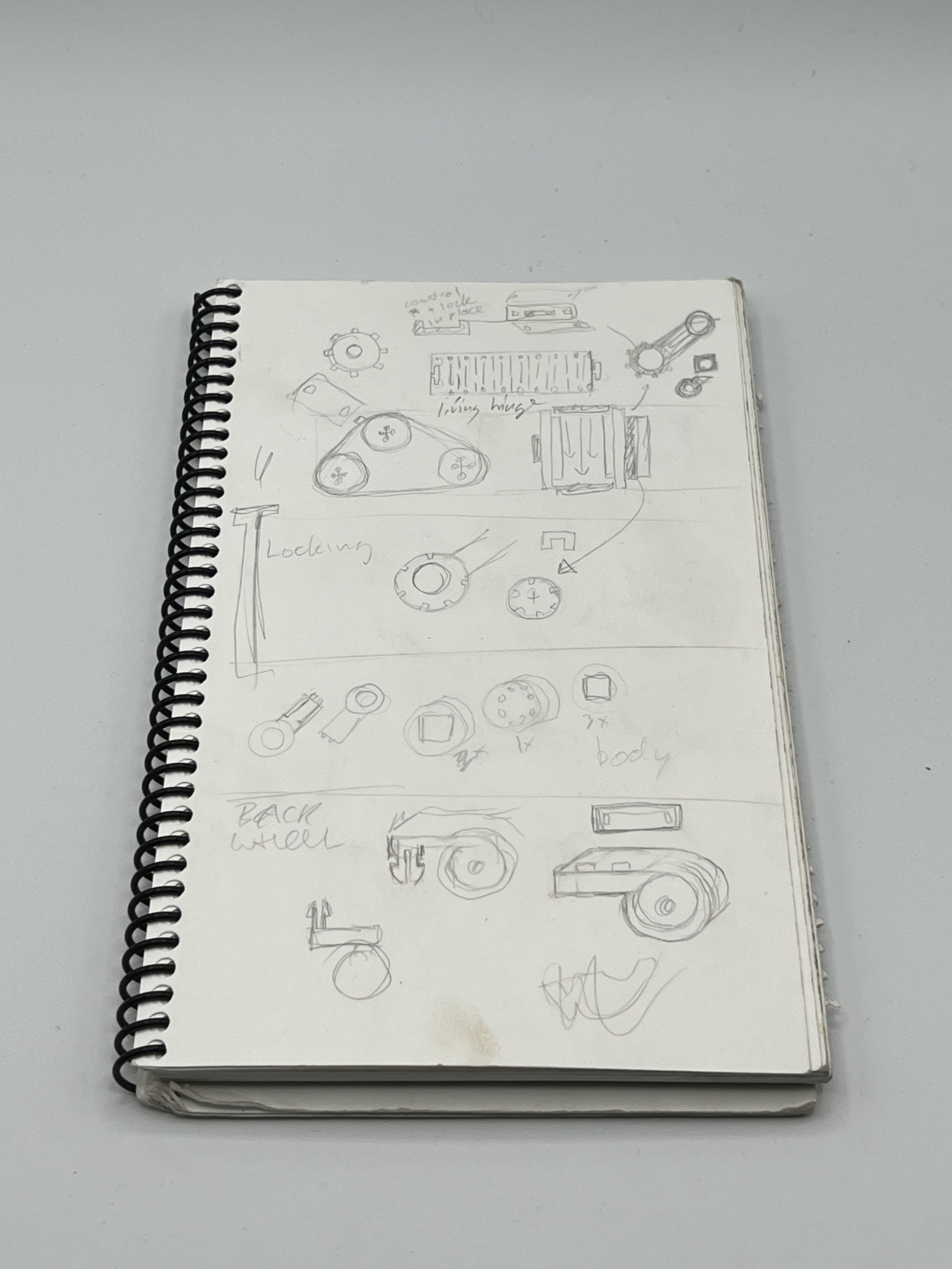

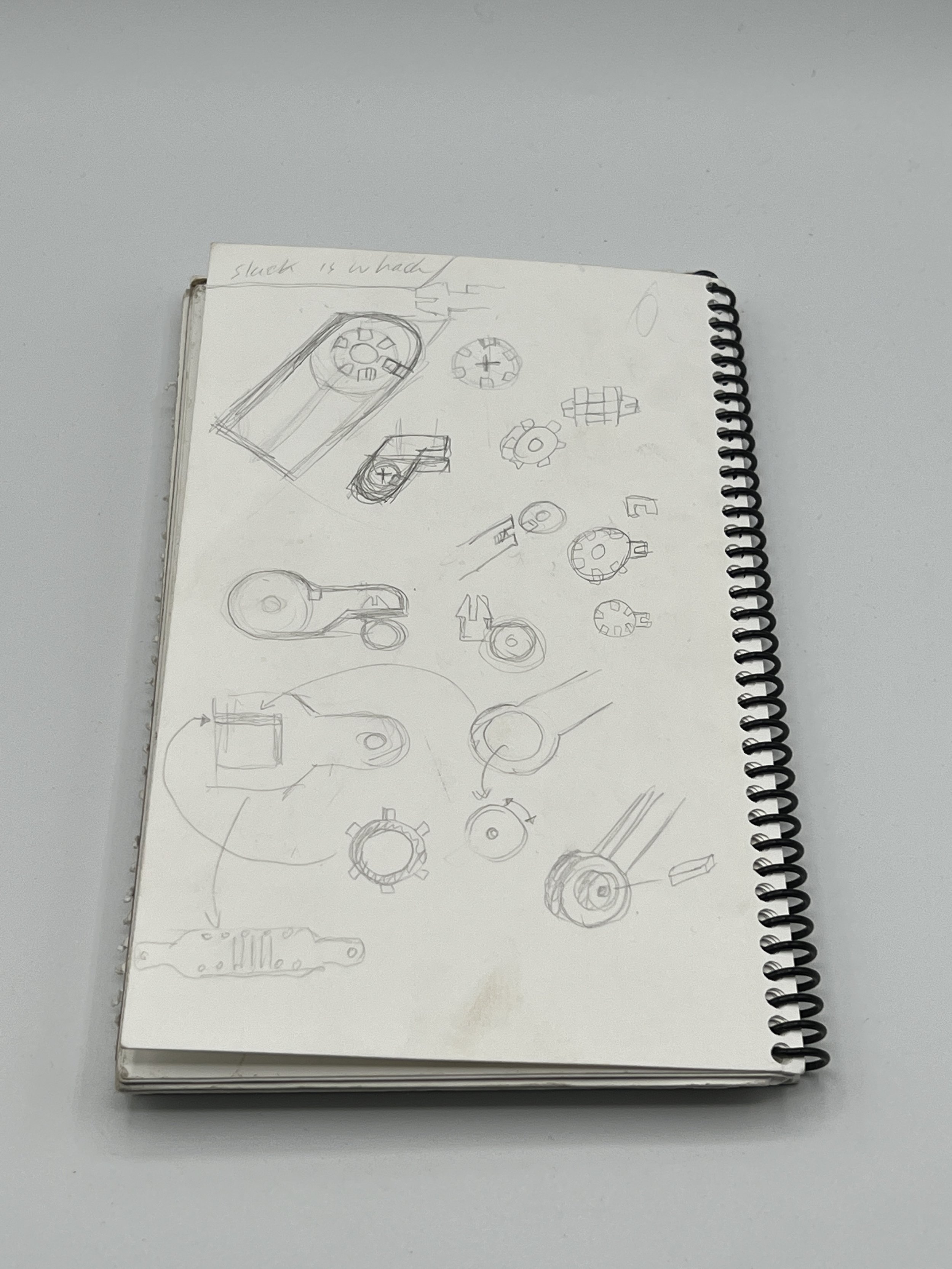

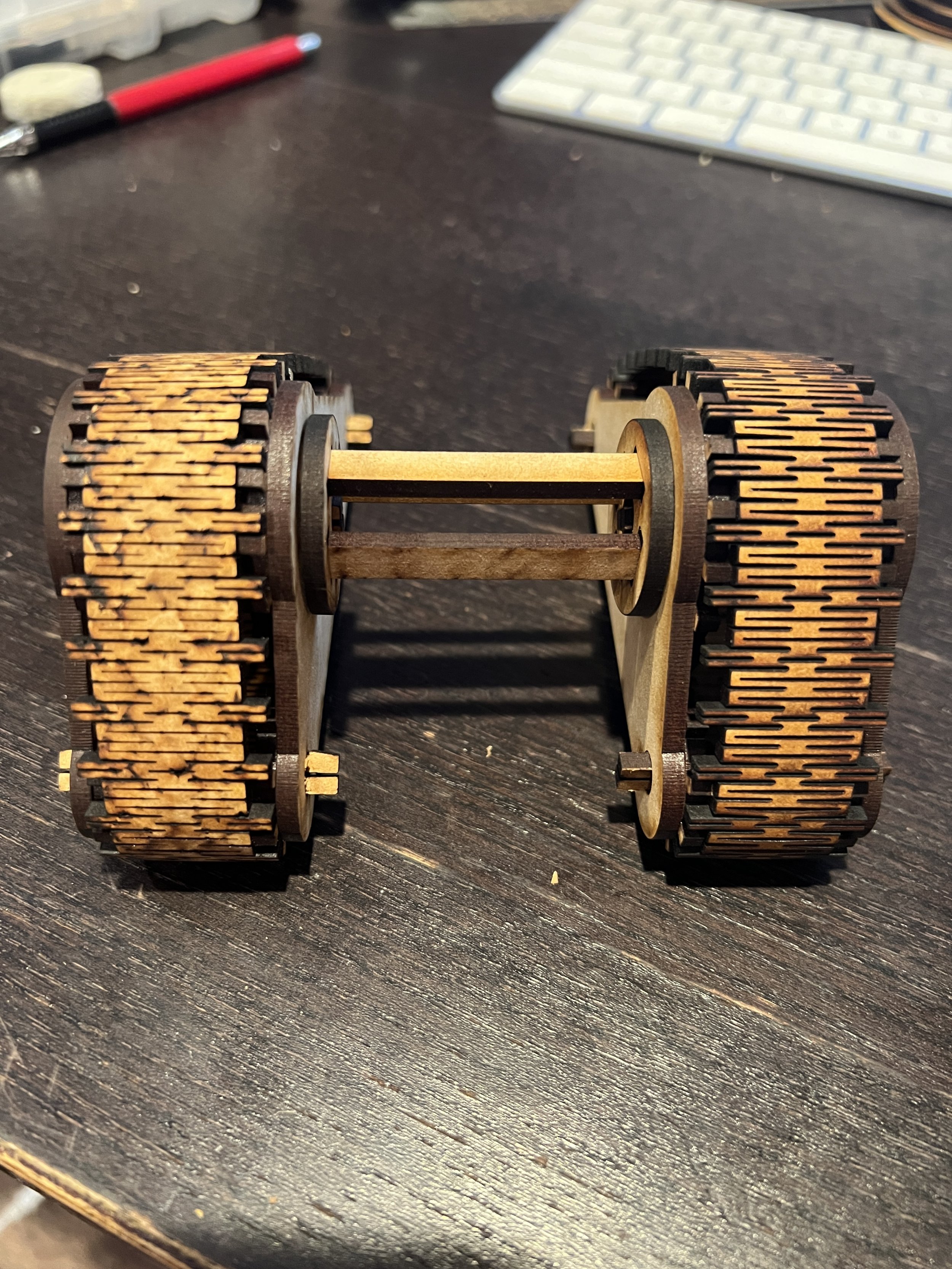

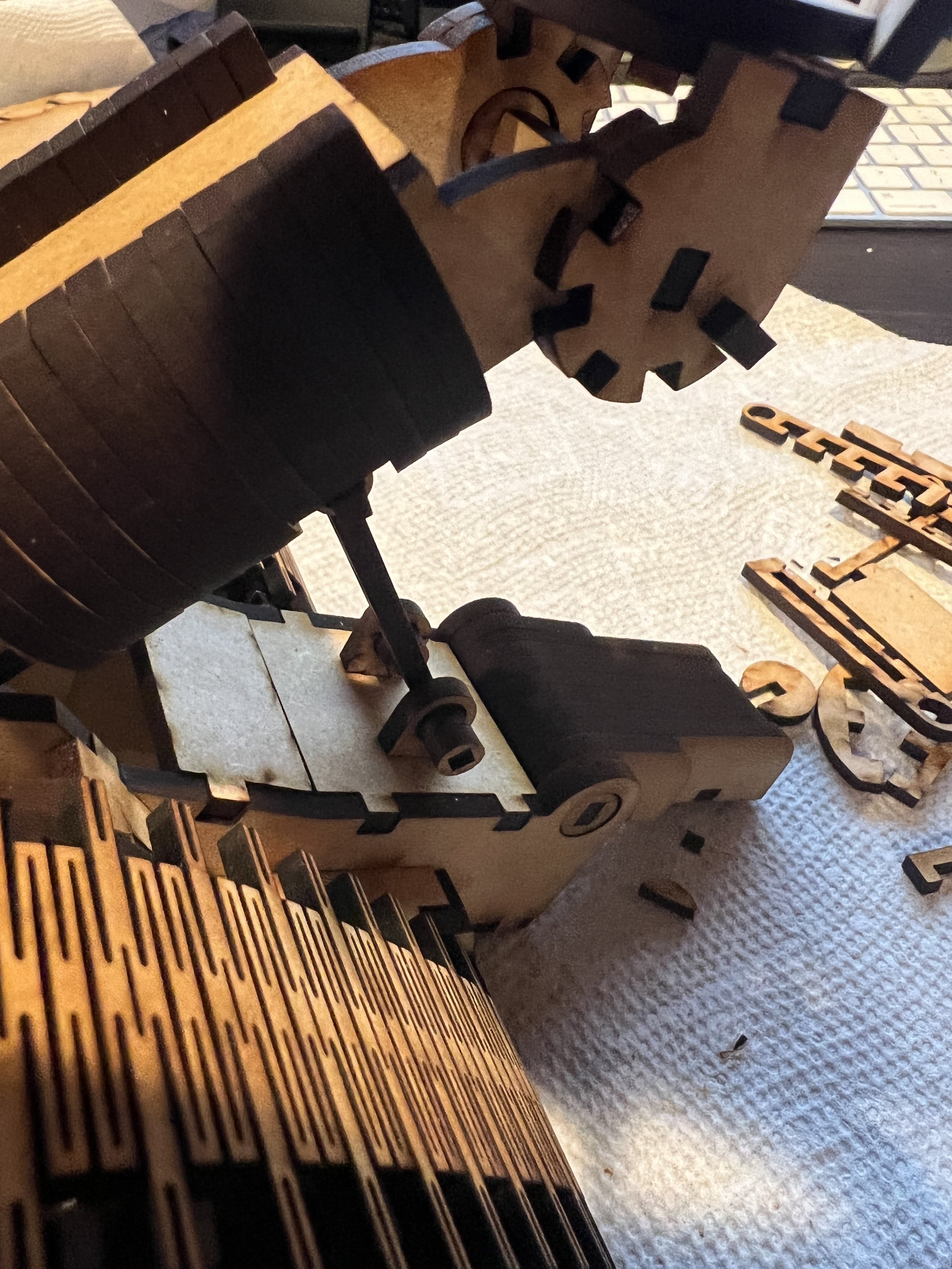

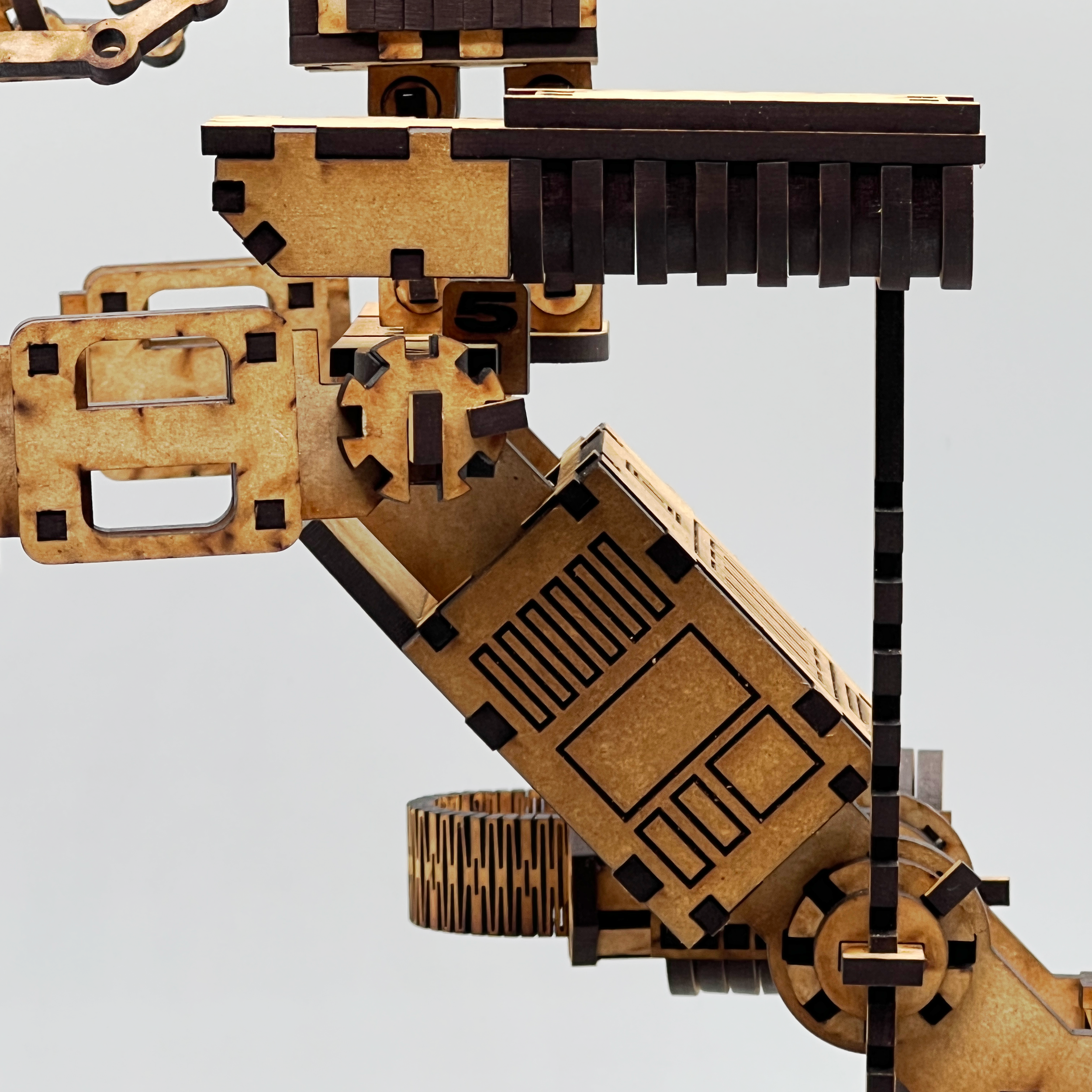

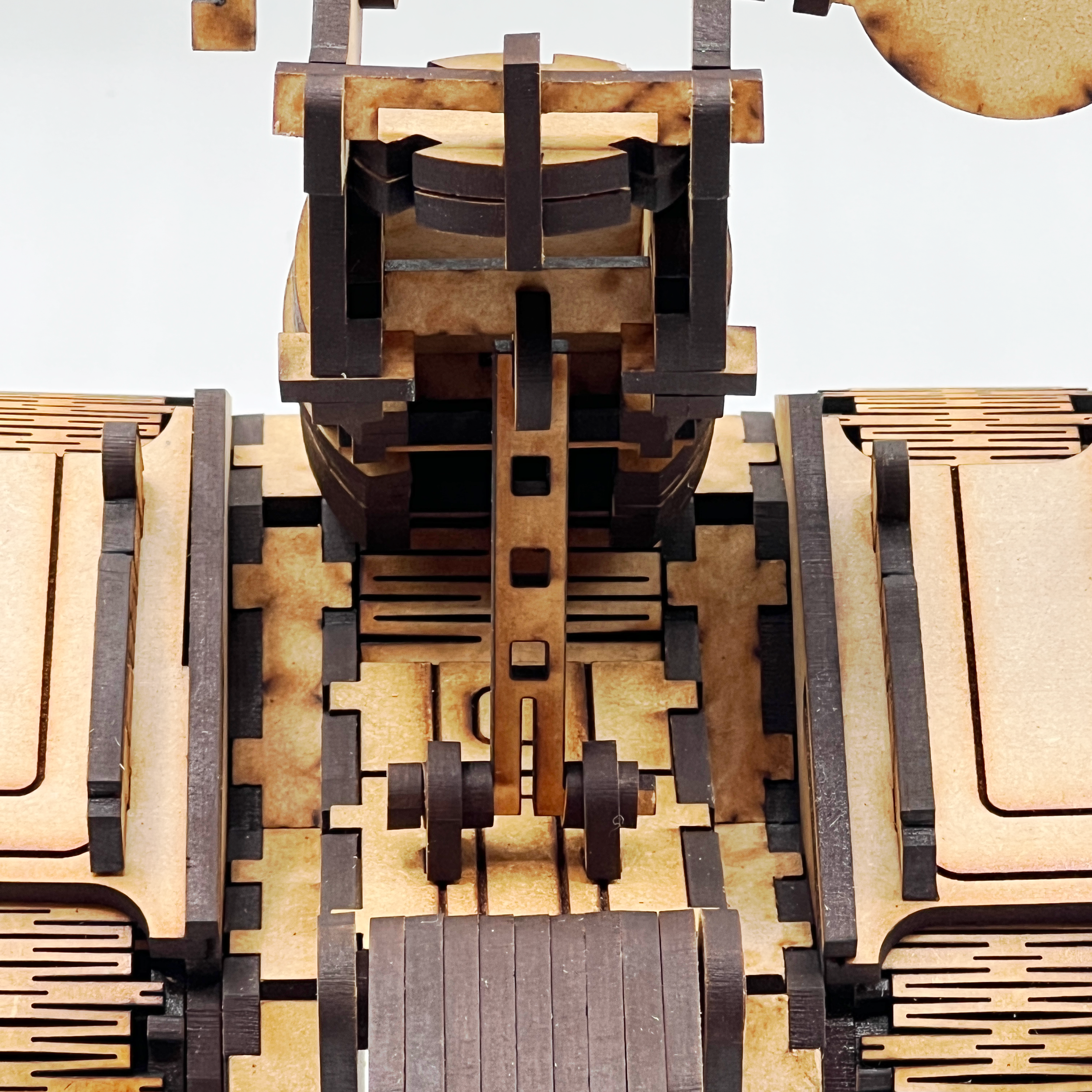

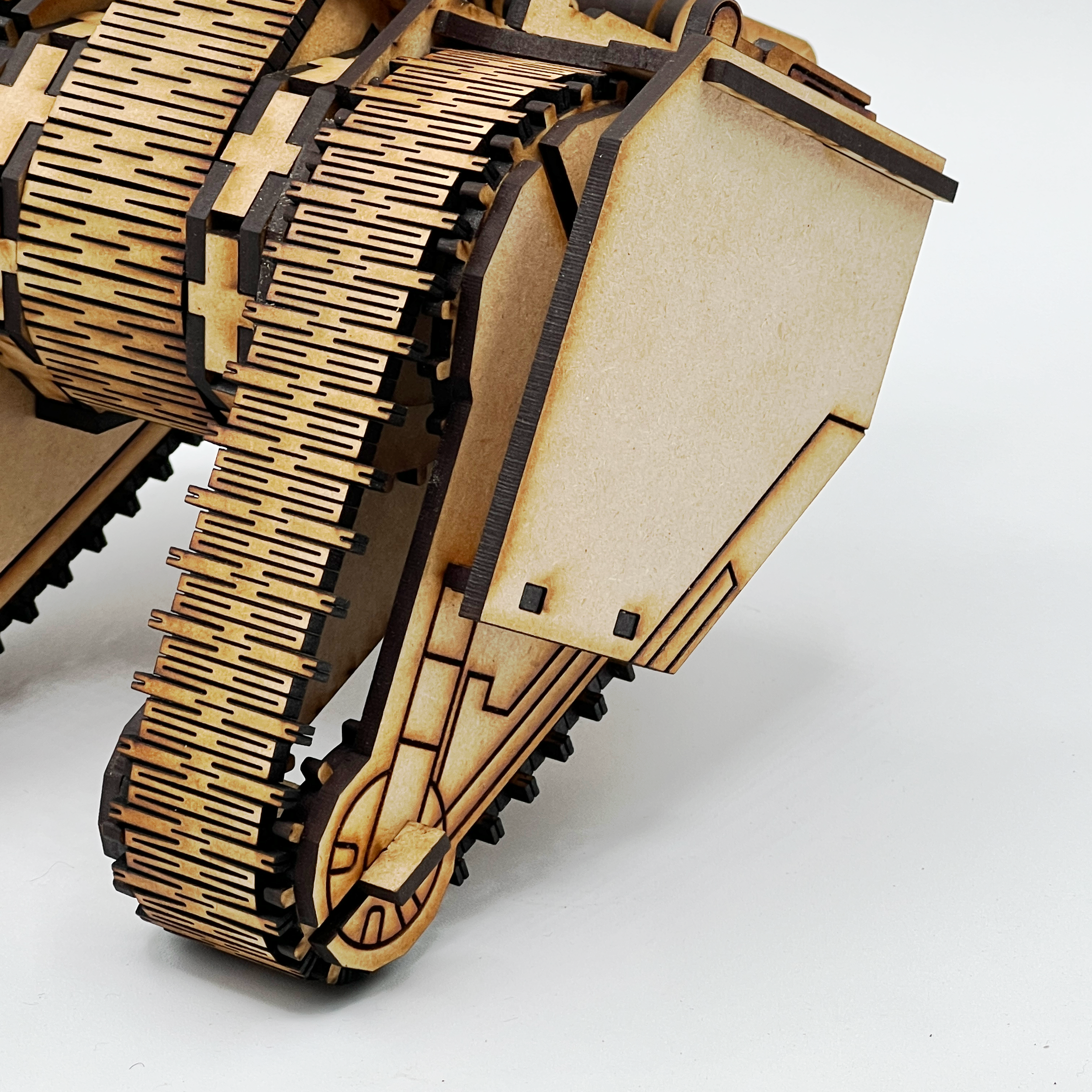

The biggest challenge was, well, everything! I’ve never built anything movable and functional out of wood. Aside from using a living hinge for treads and a few other minor details, I tried to engineer all the movable joints and make them as original as possible.

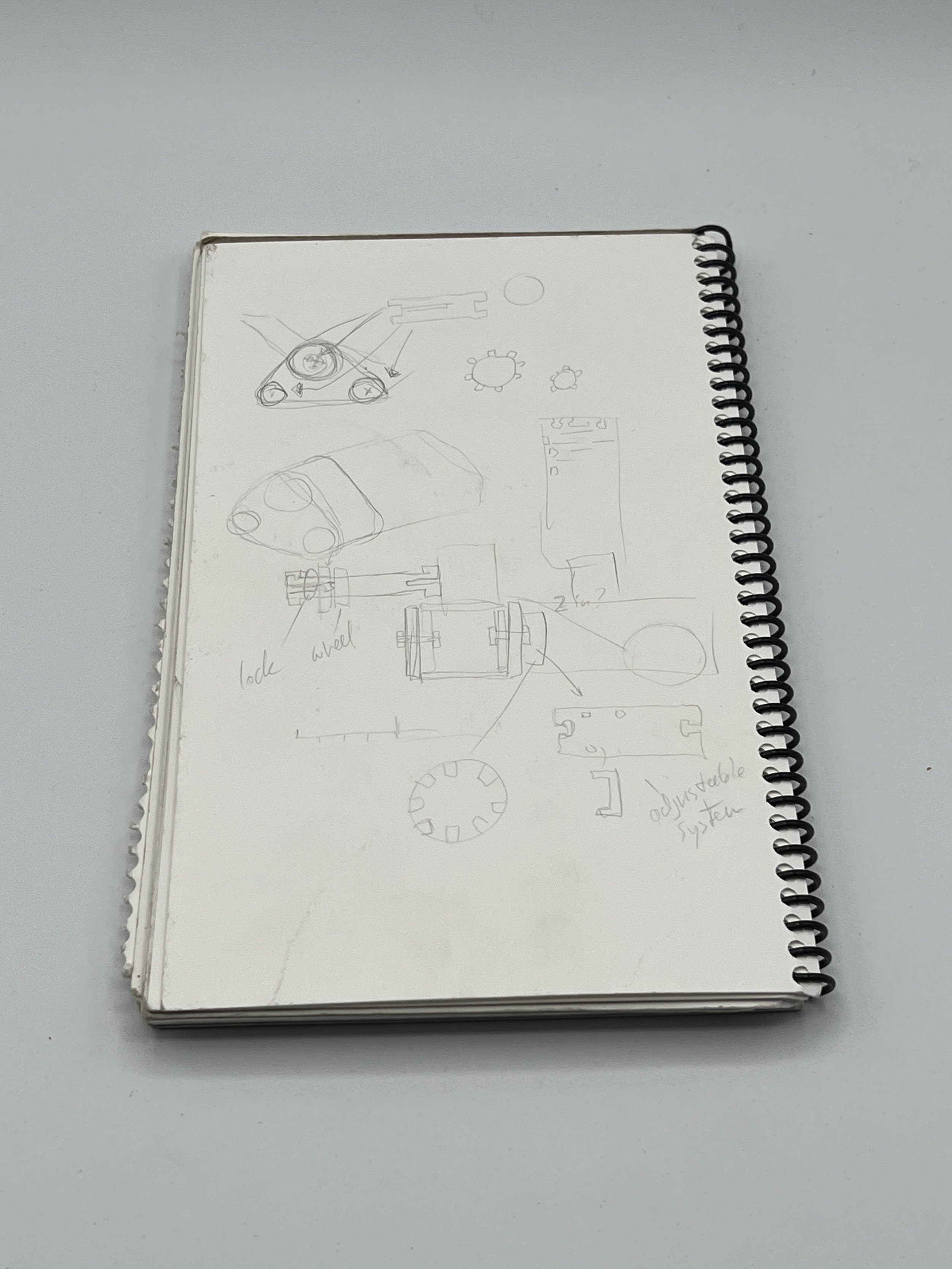

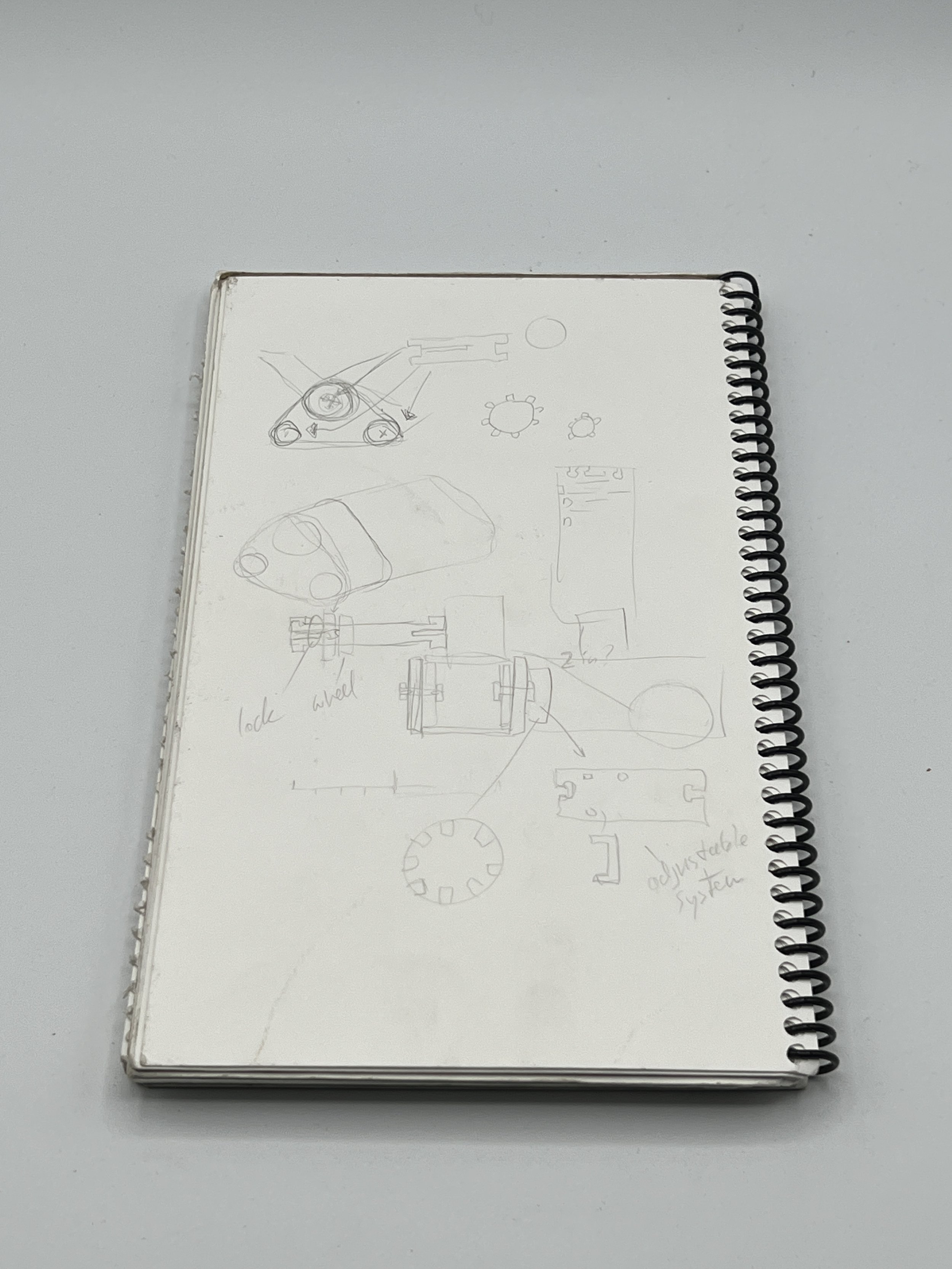

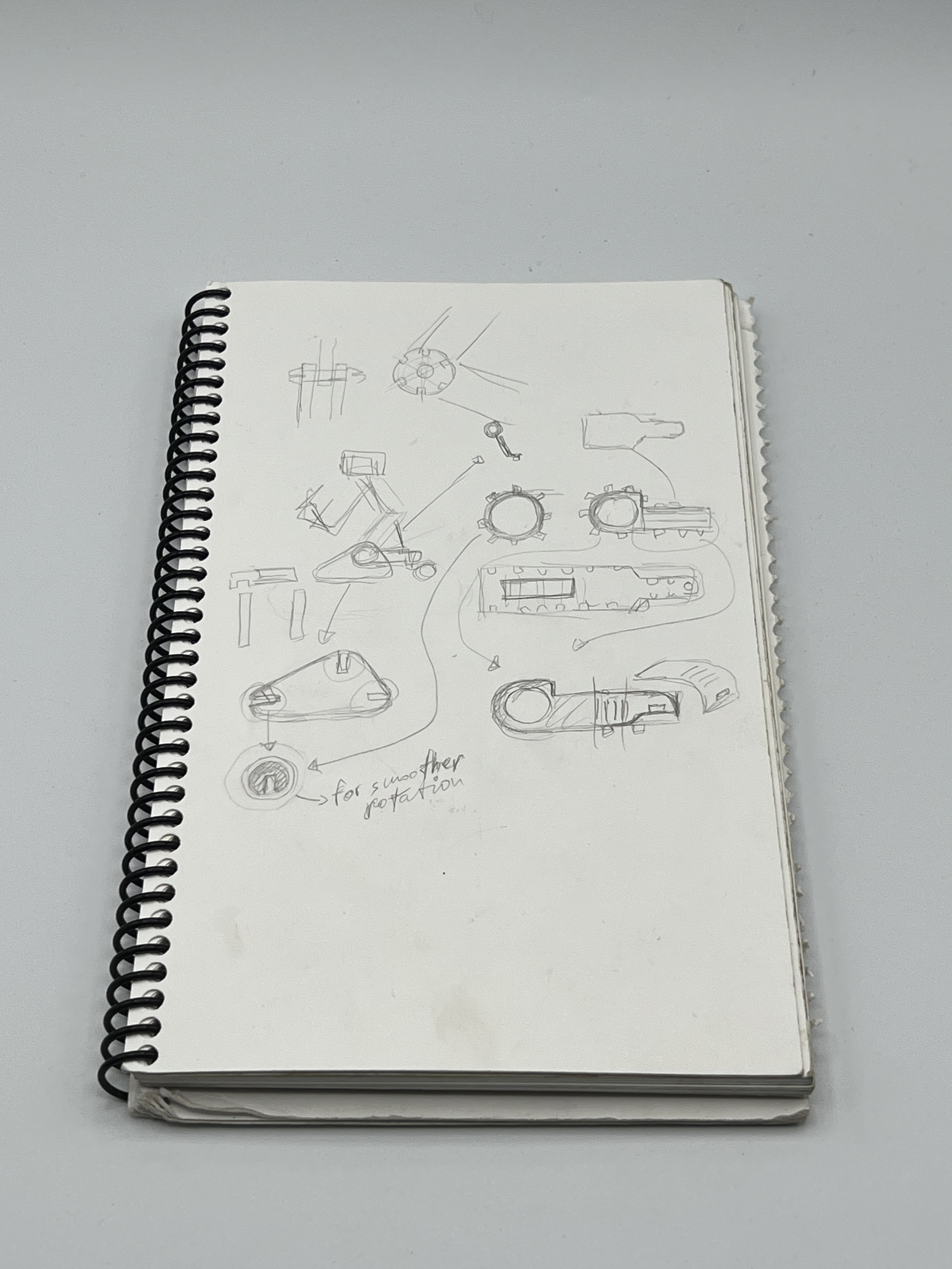

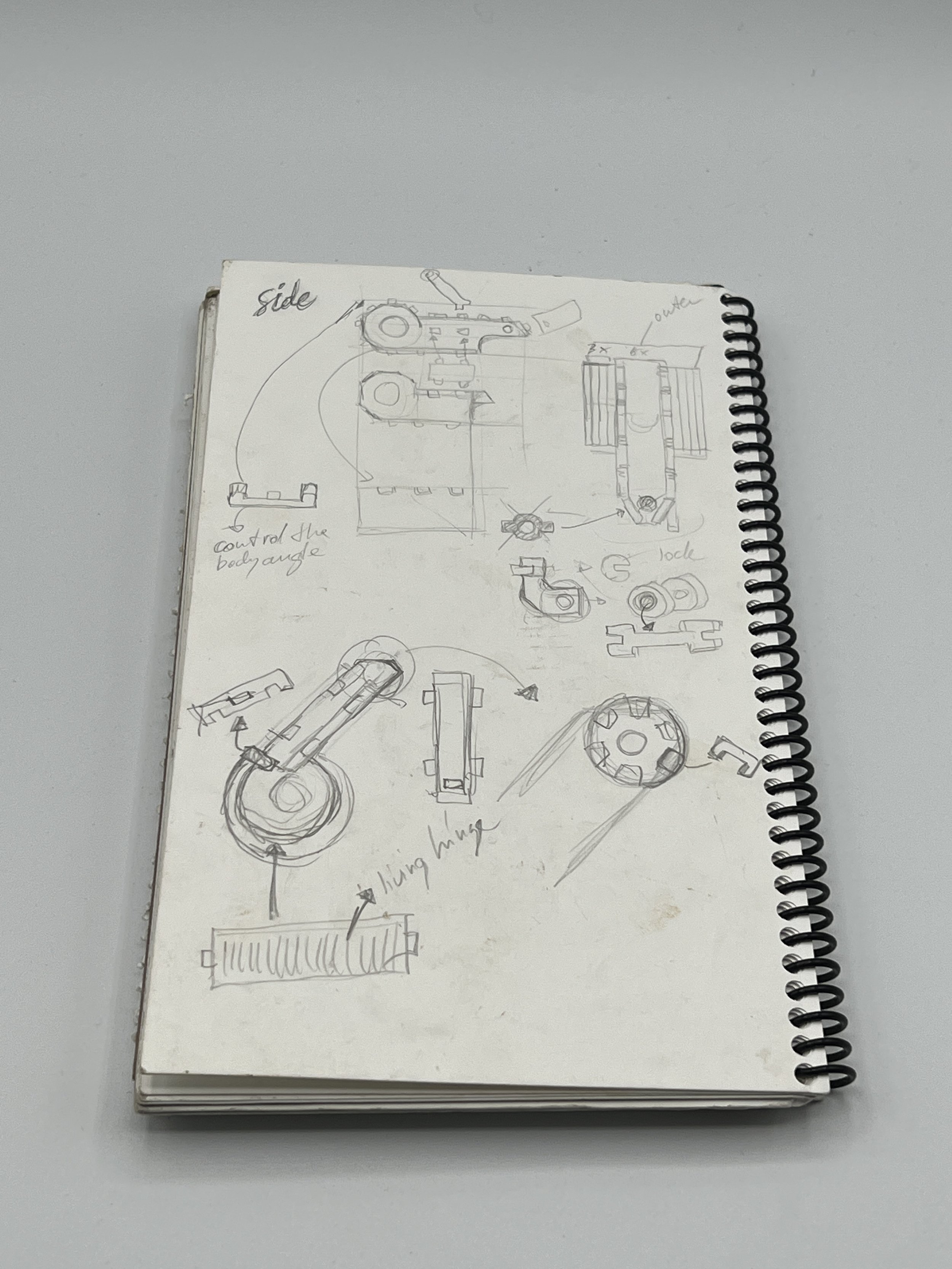

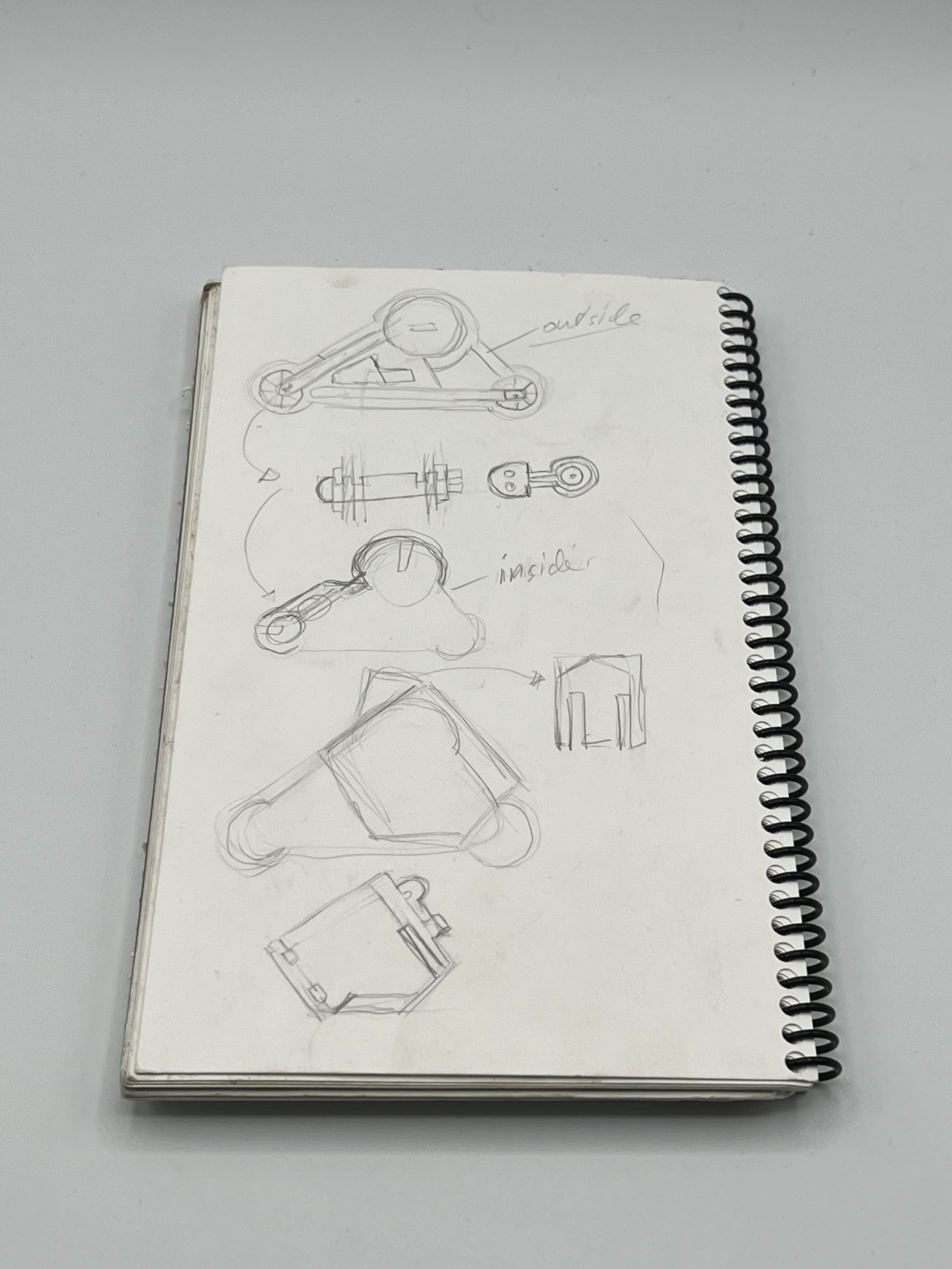

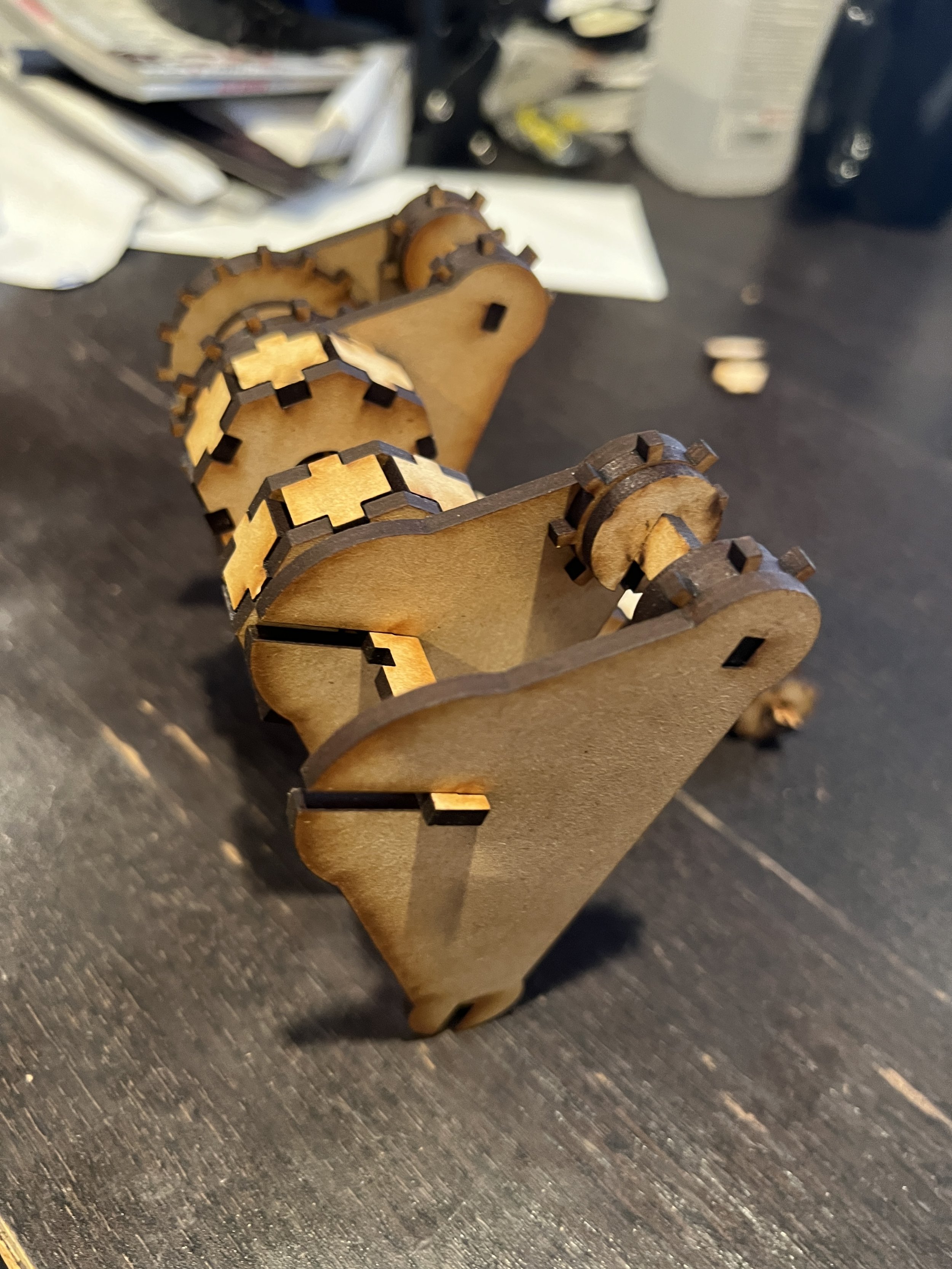

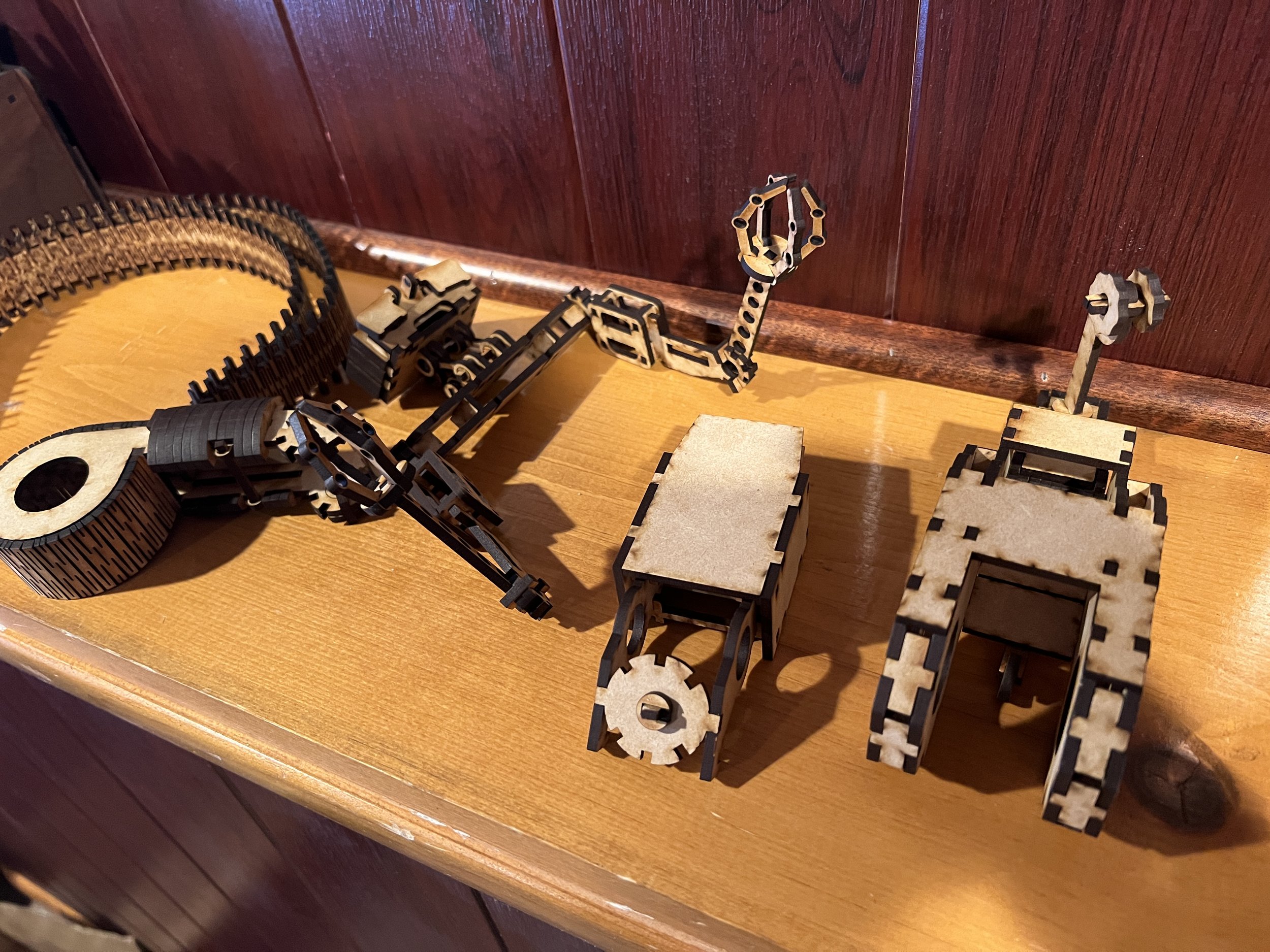

The first step were sketches, and plenty of them. I literally and figuratively started from the ground up - sketched out the treads and base first, the body frame second, the arms and head third, and other elements such as as the laser and tool belt last. As I continued sketching, I was drawing different options for each one, knowing that I would end up building quite a few of them in the process of figuring out what worked and what didn’t.

After I started experimenting with the base, I realized that I made it a. a bit disproportionate and b. too small for the thickness of the wood. So I decided to start again, making Johnny Five a bit larger this time.

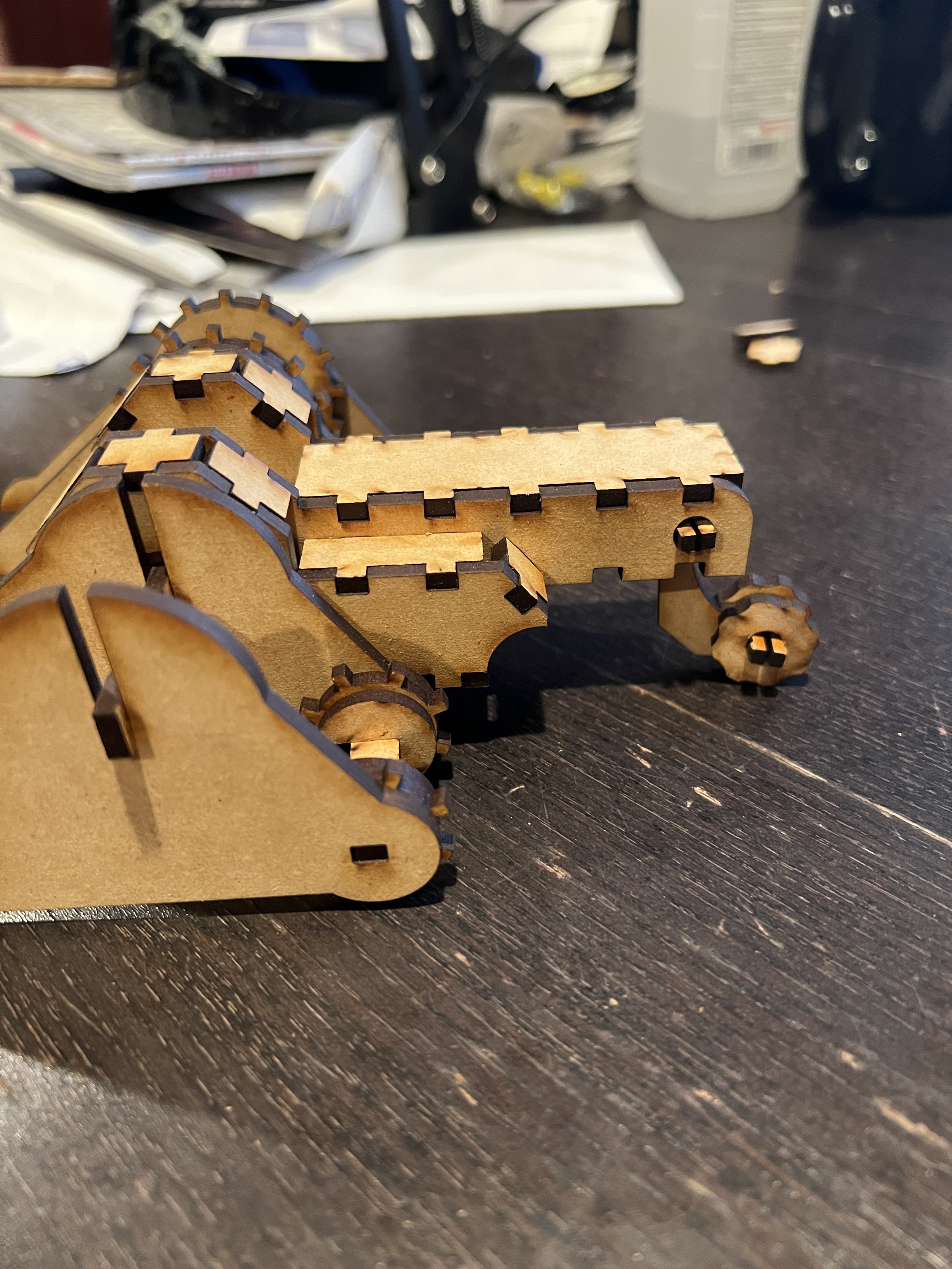

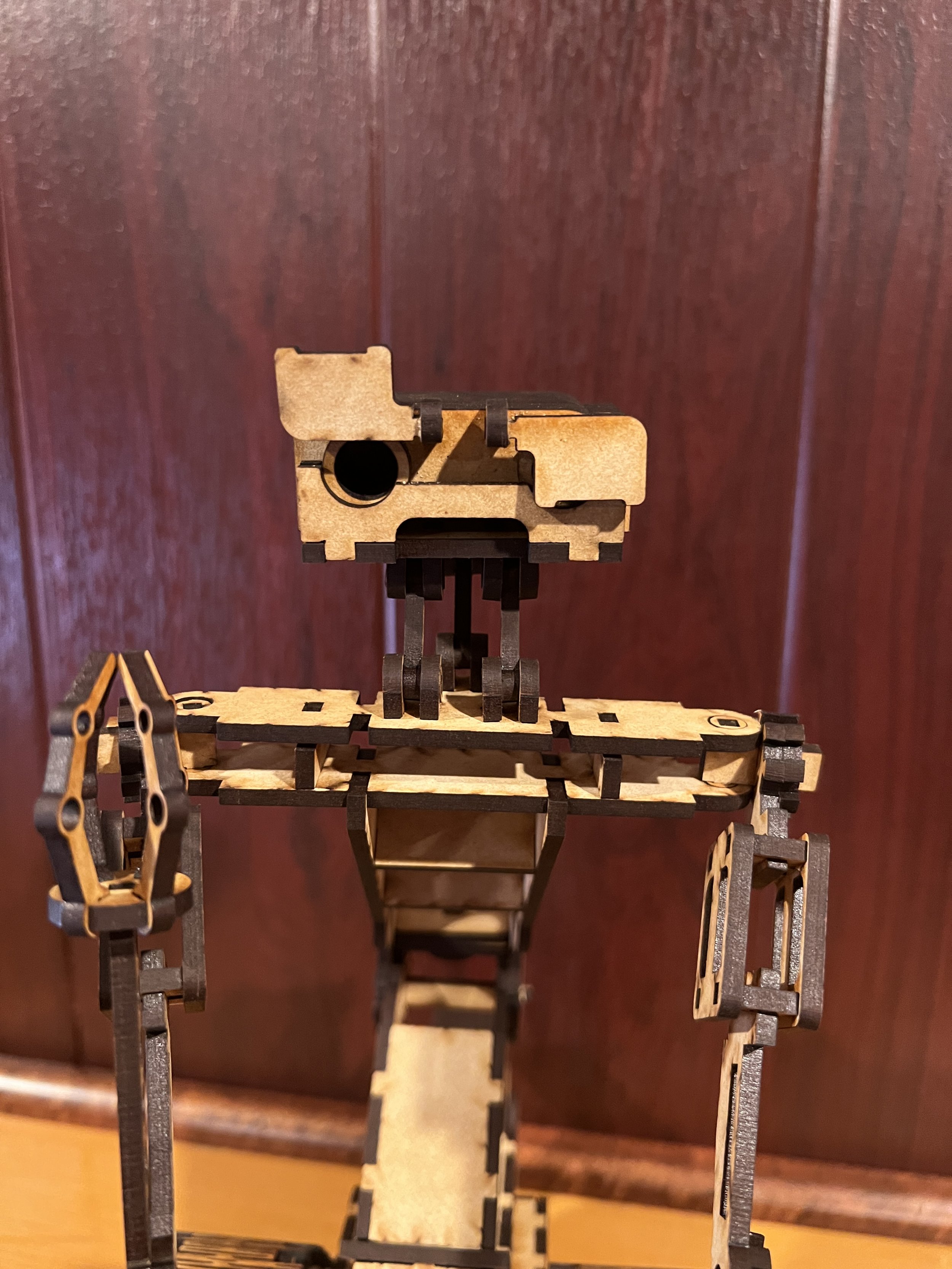

The body frame came next. By this time - about a week or so had passed - I became more familiar with the laser cutter, the nuances of working with MDF, and how the cutting process affected the functionality of the pieces. Compared to the base and treads, the body came together much easier!

With the joints, I wanted to engineer them as much from scratch as possible. While I did some quick initial research, I tried to be as original as possible with the engineering aspect of entire project, and that included quite a few failed hinges that didn’t work at all or didn’t work once I put them in context of the actual robot.

The heads and arms needed to be as movable as possible. I wanted Johnny Five to be able to convey some emotions, and I knew I was limited in part by the thickness of the wood, so I tried to give him as much mobility as possible!

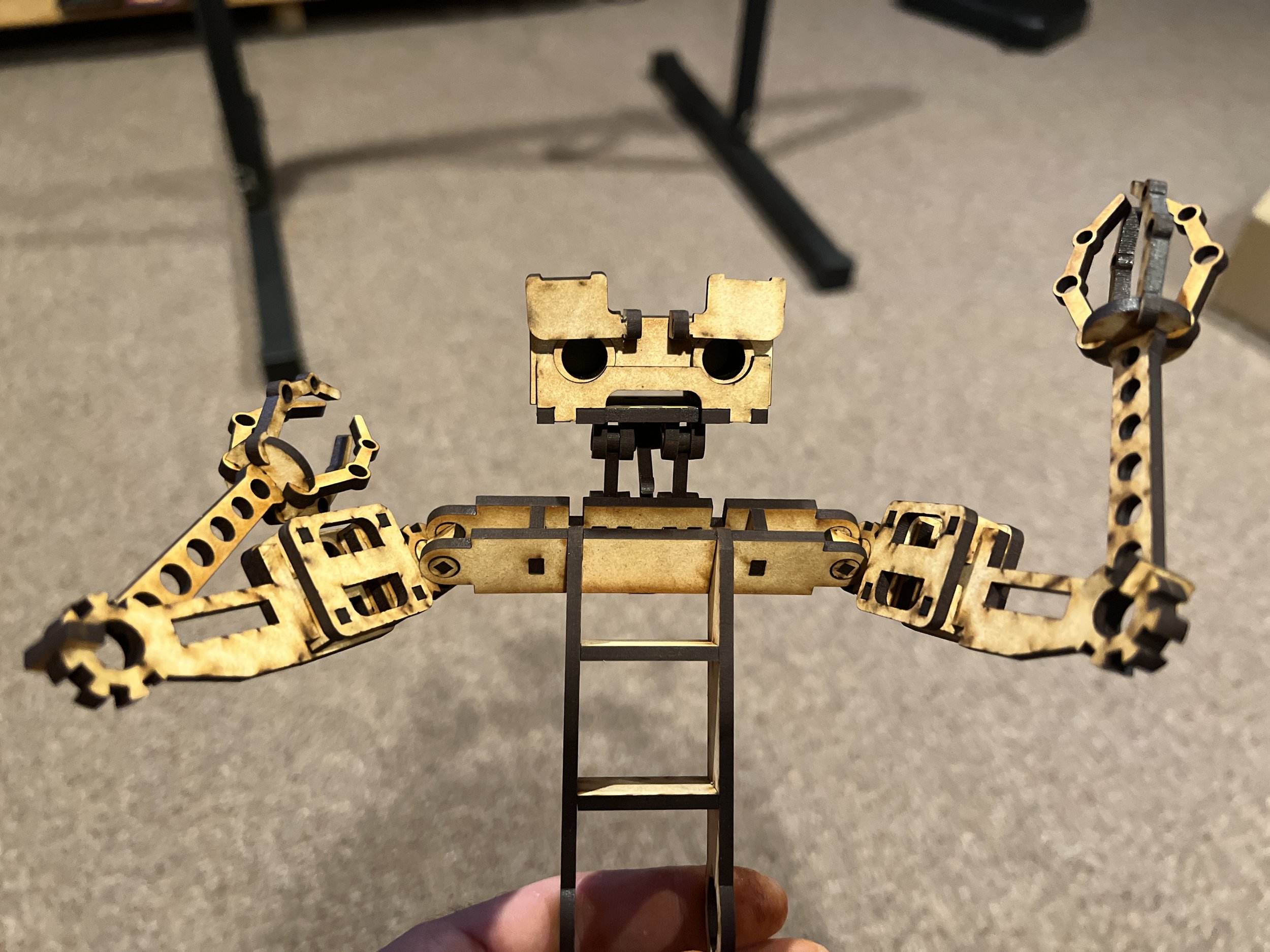

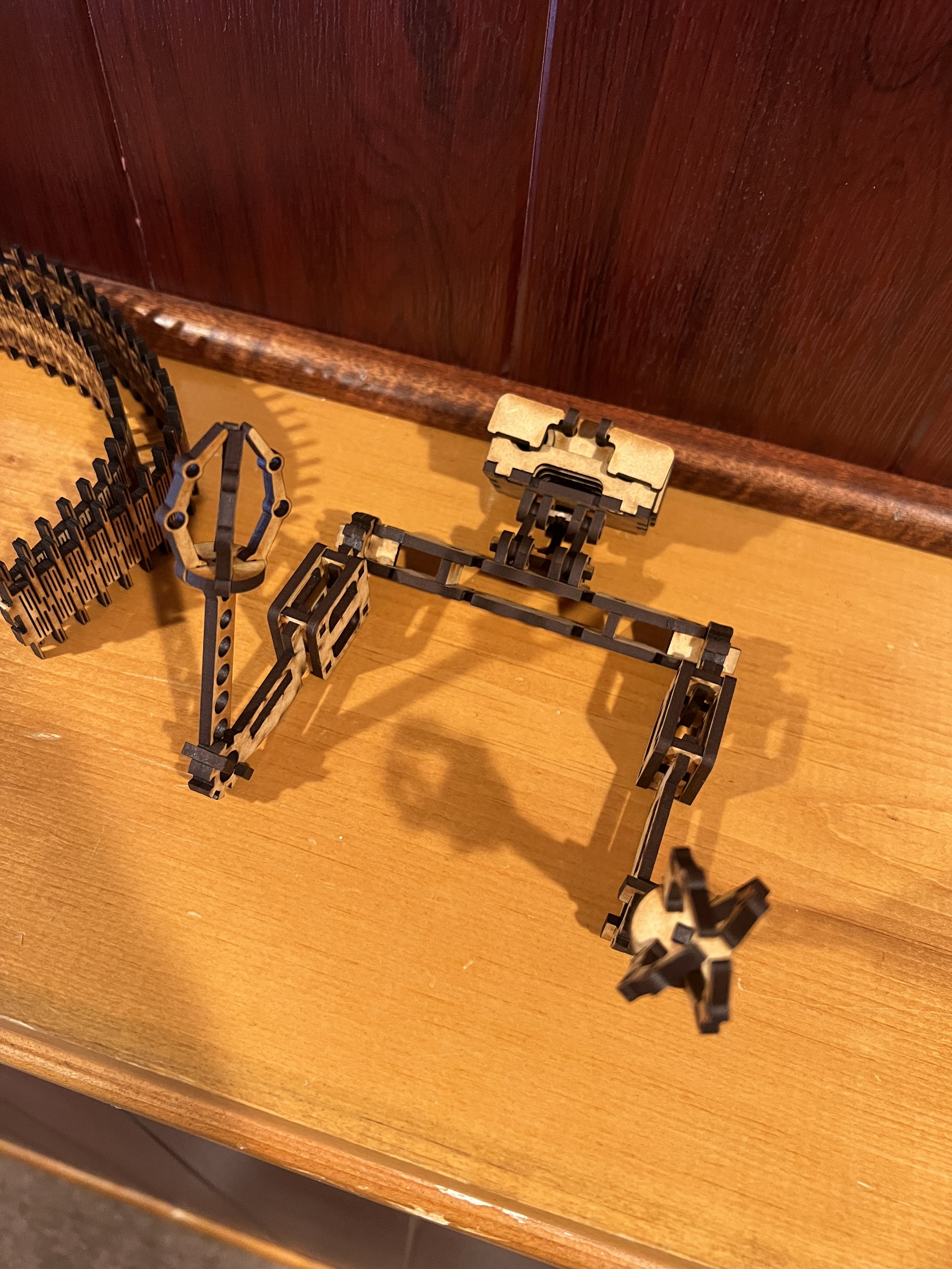

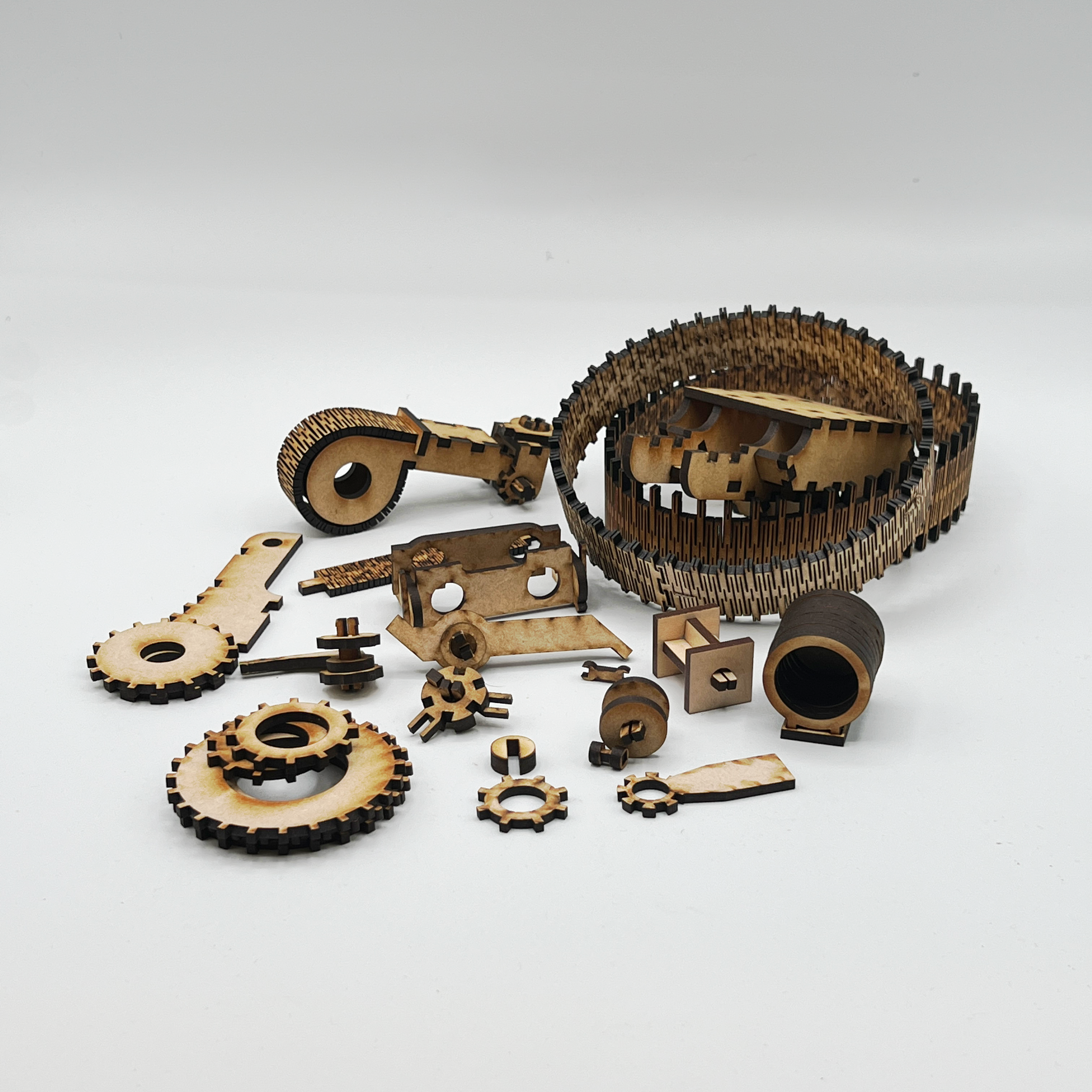

Johnny Five disassembled - to soon be assembled!

After I prototyped & cut out all the pieces, I assembled into the separate components to test them out and make sure everything worked! To my surprise, everything came together pretty smoothly. Now, it was time to add some of the details!

For the details, I tried to stay as true to the movie as possible. I don’t know how many times I watched Short Circuit 1 (and, yes, 2!) in the course of the three weeks that it took me to build Johnny Five, but some scenes I watched over and over to learn how he moves, gesticulates, etc. While I did have to make some creative compromises due to the nature and size of the materials, the details turned out well.

After all the details were added and Johnny Five was fully assembled, it was time to create some of his best quotes from the movie. Why? For the photoshoot, of course!

Finally, I wanted to share just some of the parts I cut out in the process of building Johnny Five. I don’t know how much MDF I used or how many parts I cut out - but every bit was worth it!